Justification of investing in CAD for engineering companies

CAD is an investment for companies, it is on average £3000 for a licence for software. This, however is not the only thing you have to buy as CAD users must be sufficiently trained to use it effectively, another thing to consider is the cost of buying a computer that is powerful enough to run the software as it is very demanding on hardware. However, once you have invested in the training it will last forever or possibly until new and improved software is introduced and the computer should last for several years (usually around 5) before either needing to be upgraded or replaced. Although CAD may be an expensive investment in the first place it will not take long to make the money invested back and turn it into a profit. The main reason for the investment being made back quickly is how much production speed is increased, one of these reasons is the commands such as array and copy which allow parts to be produced not only faster but more consistently accurate as it lowers the risk of human error. Because of these reasons CAD software allows you to make designs much faster and reduces the amount of rework that will have to be completed due to human error. By using CAD you are opening up the third dimension while designing, in comparison to manual hand drawing this is very beneficial as you can freely rotate your design to view and update it from different angles. If you were to try doing this with hand drawing you would have to do multiple drawings from different angles which would be very time consuming. You are able to use CAD parts that have been created by someone else and you can then import them to use in your own model. This saves a lot of time because you don’t have to draw these parts yourself.

You can use this method to pass on CAD parts that your company has created to any customers that require them. In general 3D designs look more professional which is important for businesses in this industry.

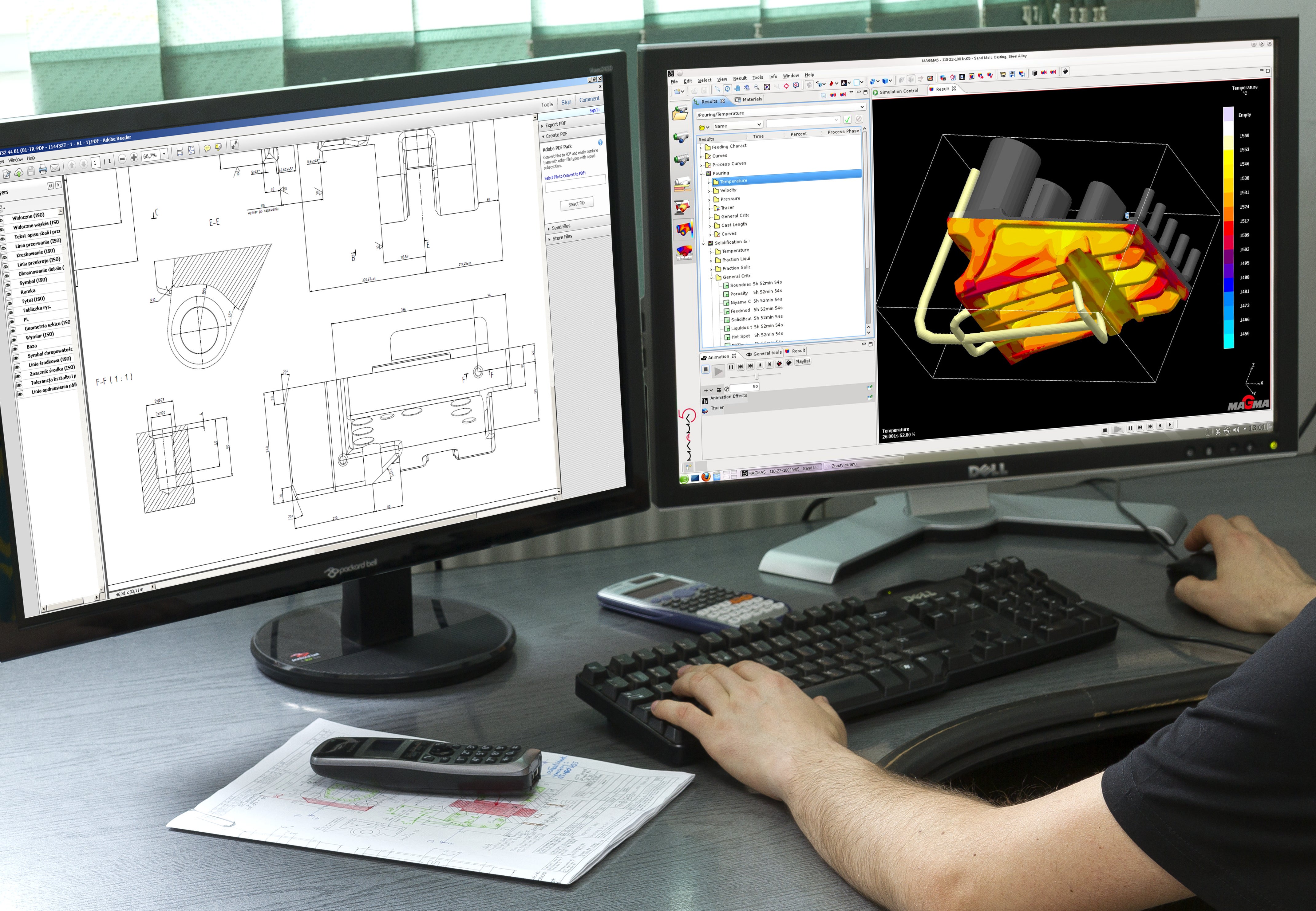

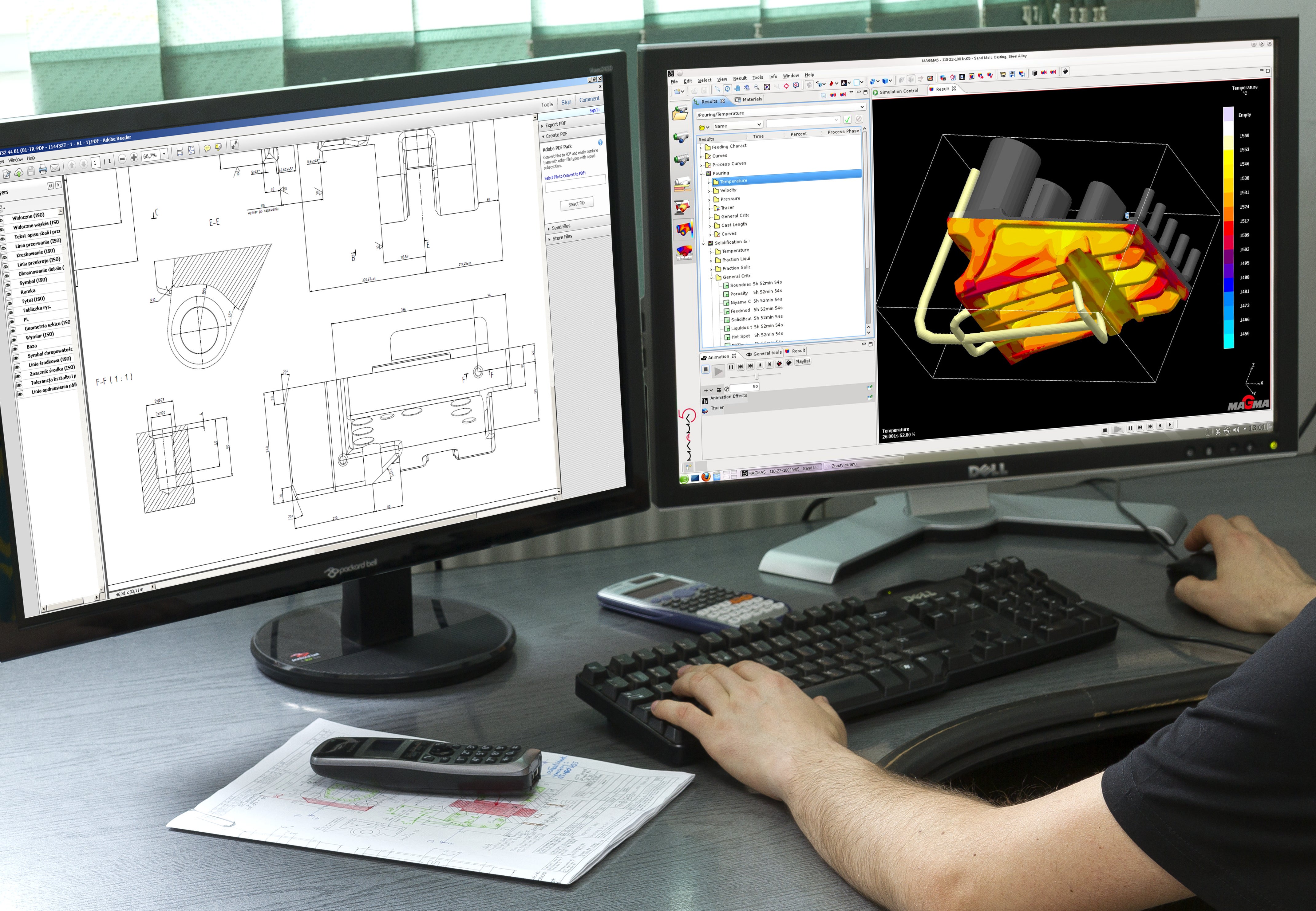

|

| Efficient use of CAD to quickly glance between several documents |

From a customer's standpoint, companies with CAD would be very beneficial when approving a design production. For a design to be approved you must show all the relevant information to the customer, this information is gained from the design specification and design brief.

This information is shown through drawings and data sheets, 2D drawings can be complex and hard to read. This is where 3D drawings are more helpful as you can view the product from different angles to make it clearer and even put it into the environment that it will eventually be in. The 3D system allows you to view a photo realistic model of the design which you can gather a lot more information from than a standard 2D drawing. From this you can gather information which can help you to proceed in the design process.

With respect to marketing and advertising, CAD is very beneficial as it makes manual processes much more effective, one example of this is being able to create models of products such as buildings can be placed into their final environment. Doing this can greatly help with planning permission and how the new build will affect the surrounding buildings, it can also show the customer how their building will look in its surroundings. Another fairly new example of CAD benefitting the marketing and advertising is being able to allowing virtual tours of the product, this is becoming more popular for the sales of boats or motor homes for example as they can look around the structure before it has been built, this allows the customer to request changes before it is built. This can be done using a viedo or through a virtual reality headset, although the headsets are quite expensive and require high power computers to use.

Comments

Post a Comment