How 3D CAD models can be used in the design process

⦁ 3D CAD models can be used to replace the manual drafting processes with a more automated process, it allows you to visualize the design from different angles and analyse the feasibility of its working. By visualizing the design you can easily spot and flag mistakes in it and witness the entire design before it has been manufactured so it removes some of the need for rapid prototyping.

⦁ A wide variety of 3D software can be used for different types of simulation, mechanical design and analysis. Kinematics programs have many different tools which allow you to test the way that a part functions and allows you to see it working before it is manufactured, this can be extremely effective for spotting issues with how the parts function with each other as sometimes there are collisions in moving parts. Some of this software has a tool called the mechanism tool which will automatically tell you if it thinks the parts are not interacting with each other as they should.

⦁ Parametric’s can be very effective in changing a 3D model with ease as you can make the 3D models driven from an external program. An example would be using the equations in a spreadsheet to change a model, the main advantage of this is that when the 3D model is driven it can be done so that when you change one dimension, the rest will change to suit it.

⦁ You can show materials of any part in an assembly after you have set the material, the material properties are true to life and more properties such as weight and strength of material can be applied. This is very important when designing for example, a part for the exterior of a sports car as it should be fairly lightweight but should also be strong enough to reduce the impact force on the driver it a crash occurred.

⦁ Another use of 3D CAD models are the fact that they can be easily imported into other CAD/CAM programs or imported into rapid prototyping machines. An example of this is seen in the fairly new trend of 3D printers, you can easily import any drawing and take it down to a printable scale. This process is completely automated, the 3D printer just extrudes material over time in intricate patterns and shapes until it is completed. Because this can be done at such a speed, it can rapidly reduce lead times. Once the prototype has been made you can then analyse the product to see if any changes will need to be made or to see if you think the overall design is feasible.

⦁ 3D CAD models are very beneficial for marketing and advertising purposes, this is because they are so detailed, high quality and look very professional. These 3D models can be easily read unlike orthographic drawings so are perfect for this purpose.

|

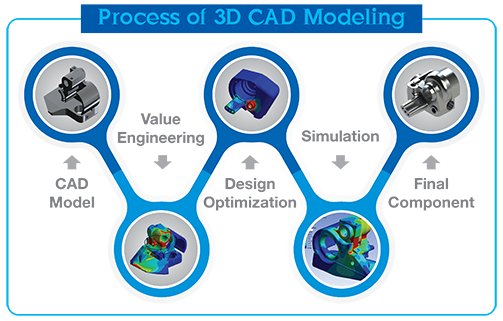

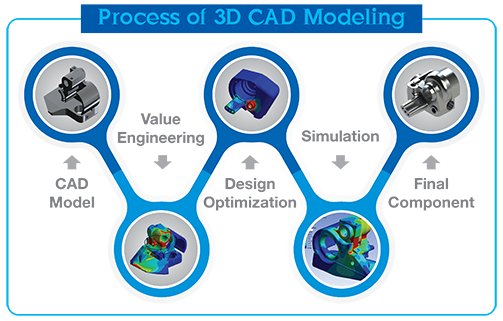

Process of 3D CAD Modelling

|

Comments

Post a Comment